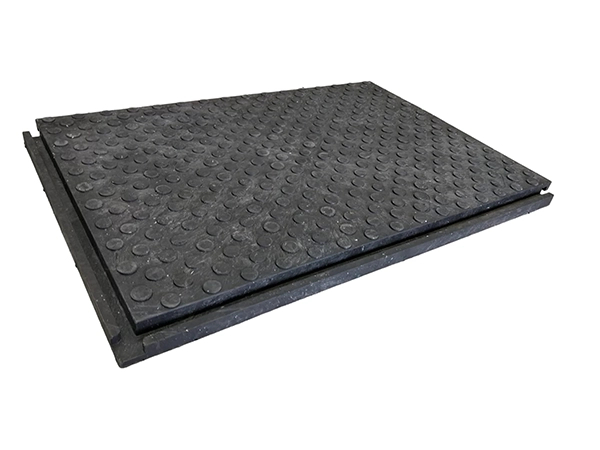

In construction, utility work, and a myriad of other industries, gaining access to tough terrains or protecting touchy floor surfaces are not unusual challenges. Composite floor safety mats, composed of a blend of materials like fiberglass, polymers, and rubber, have emerged as a sturdy answer.

Their precise composition offers them a competitive edge in durability, energy, and sustainability in comparison to conventional ground protection solutions. In this article, we explore how composite ground protection mats have become an essential asset for various industries, from construction to event management.

Composition and Material Selection

Composite ground safety mats are designed to resist heavy hundreds, harsh climate situations, and common usage. They commonly include a mixture of substances which include fiberglass, polymers, and rubber.

This mixture is strategically decided on to enhance particular traits, along with energy, flexibility, and resistance to chemical substances and UV rays.

The fiberglass component provides notable tensile electricity and flexural pressure, ensuring the mat remains stable underneath heavy masses. Polymers, which include excessive-density polyethylene (HDPE) or polypropylene (PP), are selected for his or her resistance to corrosion, chemical substances, and abrasion.

These polymers also upload an element of flexibility to the mat, making it easier to contour to extraordinary terrain shapes. Rubber components contribute to the mat’s sturdiness, shock absorption, and traction, making it a safer option for employees and equipment.

Laboratory and Field Testing

Composite ground protection mats undergo rigorous testing in each laboratory and subject settings to make sure they meet the very best requirements for power and durability. These assessments simulate various conditions that the mats might come across for the duration of use, ensuring they can withstand actual-world demanding situations.

Tensile Testing: A common laboratory for composite mats is the tensile check, which measures the mat’s capability to withstand stretching or tearing below anxiety. The mat is subjected to step by step growing force till it reaches its breaking point. The results of this take a look at help determine the mat’s tensile strength and elongation at the wreck.

Bending Testing: Another vital laboratory test is the bending take a look at, which evaluates the mat’s flexural rigidity and resistance to bending. The mat is subjected to a particular bending force, and the maximum deflection is measured. This take a look at allows check the mat’s potential to maintain its form and structural integrity beneath load.

Impact Testing: Field assessments include impact checking out, wherein heavy items are dropped onto the mat to simulate the impact of equipment or equipment. This takes a look at evaluating the mat’s capacity to absorb shocks and prevent damage to the underlying ground floor.

Field Load Testing: Mats also are subjected to heavy masses in discipline settings to simulate real-world conditions. The mats are laid on diverse terrains, and heavy machinery or vehicles drive over them to assess their load-bearing potential and the degree of floor protection they offer.

Chemical Resistance Testing: Composite mats are examined for their resistance to numerous chemical substances and environmental conditions, including exposure to oils, acids, and UV radiation. This helps make sure the mats preserve their structural integrity and overall performance over the years, even in harsh environments.

Applications Across Industries

Composite floor safety mats discover applications across an extensive range of industries, inclusive of construction, utilities, infrastructure improvement, occasions, and environmental conservation efforts.

Construction Sites: In production, these mats provide a strong and safe floor for heavy equipment and devices to function on, reducing the chance of accidents and damage to the ground.

Utility and Infrastructure Projects: During software and infrastructure initiatives, composite mats shield sensitive floor surfaces, together with grass or pavement, from harm as a result of vehicle traffic and heavy hundreds.

Events and Temporary Structures: In event planning and transient shape setup, composite mats provide a brief and dependable answer for growing strong surfaces, such as walkways and flooring, even on choppy terrain.

Environmental Conservation: Composite mats are also utilized in environmental conservation efforts, such as wetland recovery tasks. They provide transient admission throughout fragile ecosystems without causing harm to the underlying soil and vegetation.

Conclusion

Composite floor protection mats are a versatile and durable answer for protecting floor mats surfaces and offering stable access in difficult terrains. Their carefully decided mixture of substances ensures they offer advanced power, flexibility, and resistance to harsh conditions. Rigorous trying out in laboratory and subject settings ensures their reliability and performance in real-world packages. Whether utilized in construction, utilities, events, or environmental projects, composite ground protection mats are a trusted desire for shielding both the floor and the belongings running above it.